For those just stepping into the world of electronics repair, soldering can feel both exciting and intimidating. A good solder joint is not just about melting metal—it’s about creating a reliable electrical and mechanical bond that will stand the test of time. Proper soldering plays a crucial role in ensuring circuits work as intended, components remain securely in place, and repairs don’t fail prematurely. Therefore, understanding how to identify and evaluate quality soldering is just as important as learning how to perform it.

At its essence, a quality solder joint serves as both a mechanical anchor and an electrical bridge. It forms a strong connection between component leads and pads or traces on a circuit board. When properly executed, it contributes to circuit stability, minimizes electrical resistance, and prevents corrosion. Bad soldering, on the other hand, can manifest as weak joints, poor conductivity, or intermittent faults—issues that may be difficult to diagnose later on.

For beginners, the journey starts with understanding what makes a solder joint strong and reliable:

- Proper Heat Application: The right solder joint is created when both the component lead and the pad are heated sufficiently before solder is applied. This ensures the solder flows evenly and bonds properly with both surfaces.

- Cleanliness Is Key: Any contaminants like dirt, oxidation, or old flux residue can prevent proper adhesion. A clean surface before soldering helps solder flow naturally and ensures better connectivity.

- Correct Amount of Solder: Too little solder leads to weak joints; too much can cause shorts or mask issues. Quality soldering is about finding balance—a smooth, even layer that forms a perfect bridge without excess spillage.

- Consistency Through Practice: Every successful solder joint depends on repeatable technique. Beginners should aim for uniform results across multiple joints rather than focusing on speed.

Overall, recognizing a well-made solder joint depends not only on appearance but also on understanding the physics behind the soldering process: adequate heating, proper timing, and clean materials form the foundation of reliable electronic repairs.

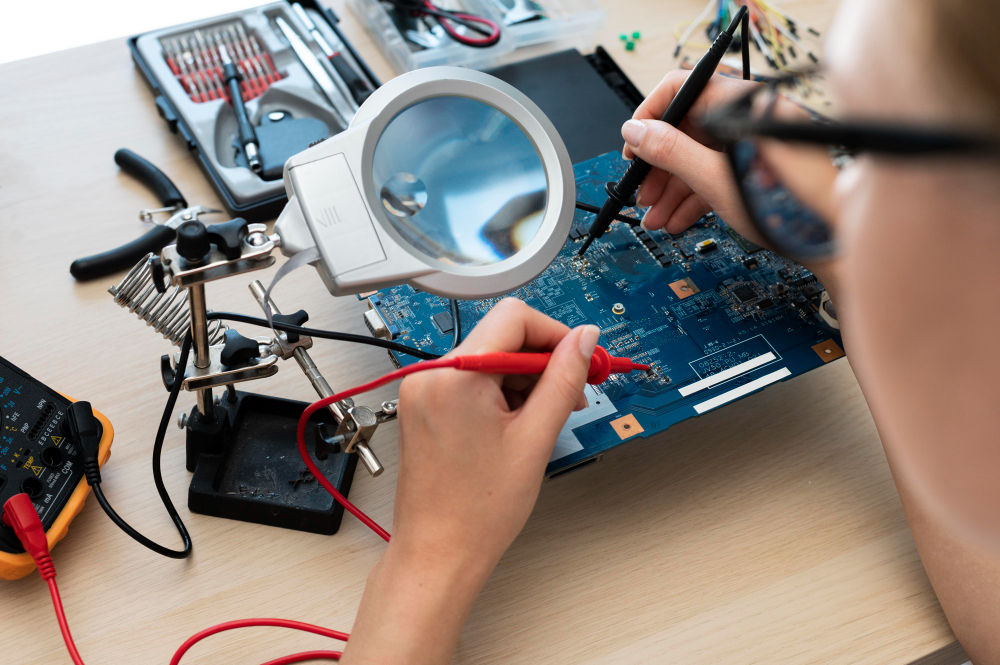

Visual inspection is often the first and most straightforward way to judge the quality of a solder joint. Even experienced technicians rely heavily on what they can see and feel before testing with instruments. For beginners, learning to identify good soldering visually and through simple testing techniques can dramatically improve repair reliability.

1. The “Smooth and Shiny” Rule

A properly formed solder joint should appear smooth, shiny, and slightly concave. The solder should flow seamlessly from the metal lead onto the circuit pad, forming a subtle volcano-like slope. This glossy finish typically indicates that the solder fully wetted both surfaces, ensuring strong electrical and mechanical contact. Dull, grainy, or frosted appearances may signal a “cold solder joint,” which results from insufficient heat or rushed technique.

2. Joint Shape and Flow

Look for a natural flow of solder that gently tapers from the lead to the board. The solder should not ball up or pool excessively. Bulky blobs, sharp edges, or overfilled joints suggest excessive solder or poor temperature control. On the other hand, joints that look too small or barely cover the pad may fail under vibration or stress.

3. Stability and Strength

Once cooled, lightly check the joint for firmness by gently nudging the component lead with a tool or tweezers. It should feel completely solid, with no wobble or movement. Any looseness indicates a weak bond. However, avoid applying pressure before the solder has cooled—disturbing the joint too early can weaken it.

4. Color and Oxidation Clues

A good solder joint often retains a bright silver tone, especially when freshly made. If the joint appears dark gray or shows visible oxidation, that may indicate overheating or exposure to air during soldering. Overheated joints can become brittle and may crack over time, creating intermittent electrical connections.

5. Electrical Testing and Continuity Checks

For functional verification, use a multimeter to test for continuity between connected points. Smooth, low-resistance readings indicate solid electrical flow, confirming that the solder joint is conducting efficiently. Beginners should make this a habit after every repair—visual inspection combined with testing ensures accuracy.

6. Clean Finish and Minimal Residue

A professional solder joint should have minimal flux residue or debris around it. While some flux residue is common, excessive buildup looks messy and can lead to long-term corrosion if not cleaned. For best results, use isopropyl alcohol and a clean brush to remove any sticky residue once the soldering is complete.

Recognizing quality soldering comes down to understanding both the science and artistry of the process. Beginners in electronics repair should focus on producing joints that are clean, shiny, structurally sound, and electrically solid. Over time, your eyes and hands will develop sensitivity to temperature, solder flow, and timing—skills that transform simple soldering into genuine craftsmanship.

In the field of electronics repair, precision and patience always pay off. Every time you examine your work critically, comparing what you see to the benchmarks of professional soldering, you reinforce your ability to create dependable, long-lasting connections. Quality soldering isn’t just about fixing gadgets—it’s about building a foundation of reliability in every circuit you touch.