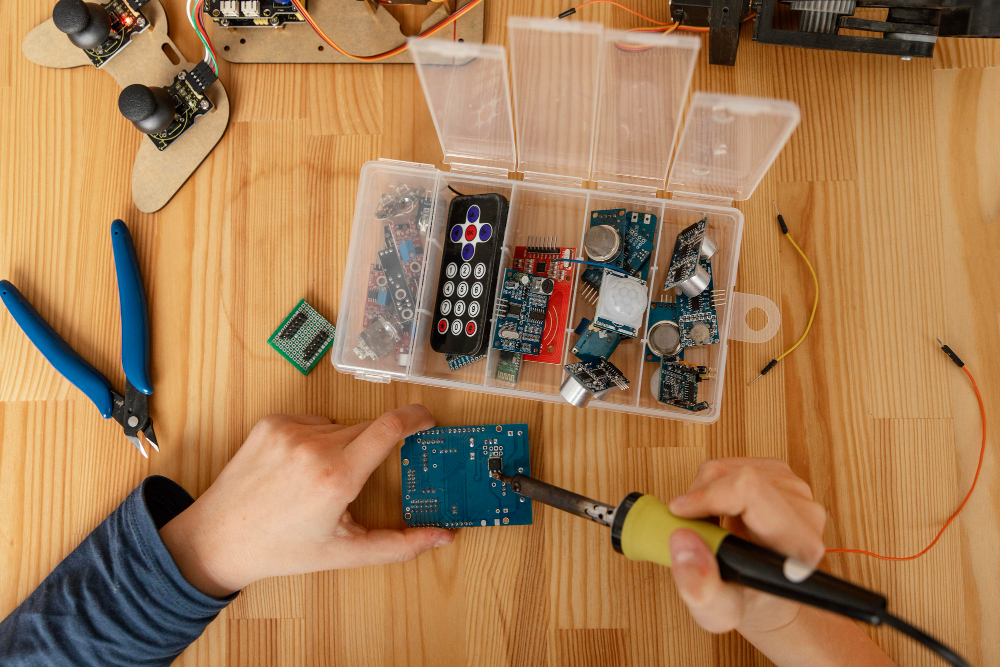

In the world of digital design and automation, the landscape of embedded computing has never been more dynamic. What once required dedicated engineering teams and proprietary hardware can now be prototyped on a hobbyist’s desk for a fraction of the cost. The rise of accessible electronics platforms has reshaped how we think about product development—from quick one-off experiments built with inexpensive boards to scalable devices that power industrial systems.

Microcontrollers (MCUs) and single-board computers (SBCs) sit at the heart of this evolution. Both play crucial roles in modern embedded design, but they serve distinct purposes. Understanding their differences—and how they complement one another—is key to navigating the line between the creativity of experimentation and the discipline of industry.

At its core, a microcontroller is a compact, purpose-built computing unit: a processor, memory, and input/output peripherals all integrated into a single chip. Designed to execute simple, repetitive tasks reliably, microcontrollers thrive in environments where efficiency, low power consumption, and deterministic behavior are paramount. Whether controlling the temperature in a smart thermostat or managing the motor speed in a washing machine, a microcontroller performs its job consistently, even with limited computational power.

On the other hand, a single-board computer is more akin to a full-fledged general-purpose computer condensed into a small footprint. Think of boards like Raspberry Pi, BeagleBone, or NVIDIA Jetson. SBCs include not only a processor but also an operating system—typically Linux or a variant thereof—and the ability to connect to peripherals through USB, Ethernet, HDMI, and more. This allows for higher-level programming, complex networking capabilities, and real-time communication with cloud services. SBCs excel at handling multiple tasks or running data-intensive applications such as image recognition, machine learning at the edge, or advanced monitoring systems.

The difference between MCUs and SBCs is not merely about specifications—it’s about intent. A microcontroller-based design usually targets simplicity, stability, and cost efficiency, while a single-board computer-based design leans toward flexibility, multimedia performance, and connectivity. Yet, both categories have evolved. Modern microcontrollers are adopting features such as wireless communication (Wi-Fi, BLE, LoRa) and higher clock speeds, narrowing the performance gap. At the same time, SBCs have become smaller and more power-efficient, making them viable in environments previously dominated by microcontrollers.

As engineers, makers, and innovators move from prototyping to production, the boundary between “hobby” and “industry” becomes both apparent and blurred. In early stages of a project, experimentation thrives on adaptability—hobbyists working with SBCs can swiftly test new ideas with Python scripts or pre-built libraries, leveraging open-source communities for immediate results. However, when a product moves toward commercialization, priorities change. Cost per unit, reliability over years of operation, supply-chain stability, and compliance with industrial standards start to dominate design decisions. Under these constraints, the compact, stable, and deterministic nature of a microcontroller often becomes the more appropriate solution.

Yet, this is not a simple handoff between one platform and another. Many successful industrial systems today combine both technologies. For example, an industrial sensor node may rely on a microcontroller for real-time data acquisition and on an SBC as a gateway to process, visualize, and transmit data to the cloud. This hybrid approach merges the predictability of MCU control with the computational flexibility of an SBC. It reflects a broader trend in embedded design: rather than choosing one over the other, engineers strategically layer them for optimized performance.

To appreciate where hobby ends and industry begins, one needs to look not only at technical distinctions but also at the surrounding ecosystem. The explosion of community-driven projects, open-source development tools, and educational platforms has given rise to a generation of designers who began with Arduino boards and Raspberry Pis yet have gone on to build professional products and startups. This democratization of technology has shortened the feedback loop between concept and deployment. The early-stage prototype that once lived on a maker’s desk can now rapidly evolve into an industrial solution with proper engineering refinement.

However, industrial applications demand a different set of criteria: long-term component availability, rigorous quality assurance, electromagnetic compatibility, and predictable maintenance cycles. A board chosen for its convenience in a prototype may not meet the operational demands of a factory floor or a remote field installation expected to run continuously for years. This is where industrial-grade microcontrollers and specialized SBCs, designed for durability and supported with extensive documentation and lifecycle guarantees, take precedence.

At a deeper level, the evolution from hobby to industry represents a philosophical shift. Hobbyist platforms encourage quick iteration, creativity, and accessibility—they thrive on flexibility and community-shared knowledge. Industrial solutions, in contrast, prioritize robustness, security, and repeatability. Yet both are rooted in the same principle: the desire to build systems that interact intelligently with the physical world.

This transition mirrors how innovation flows today. Many ideas originate in open, collaborative, and decentralized environments, where microcontrollers and SBCs serve as experimental units. Once validated, these concepts are refined through engineering rigor, optimized firmware, and hardware reliability. What emerges is not just a product, but a proof of how democratized innovation scales into industrial reality.

In conclusion, the boundary between microcontrollers and single-board computers is less a clear demarcation and more a gradient of purpose and constraint. The choice between the two is rarely about which is “better,” but which is “right” for the job. Hobbyists may begin with flexibility, learning through rapid prototypes on an SBC, while industrial designers may converge on purpose-built microcontrollers for efficiency, stability, and scale. Together, they define the continuum of modern embedded design—a journey that starts on a workbench, takes shape through experimentation, and ultimately powers the complex, interconnected systems that keep industries running.